Development / Construction / Project Management

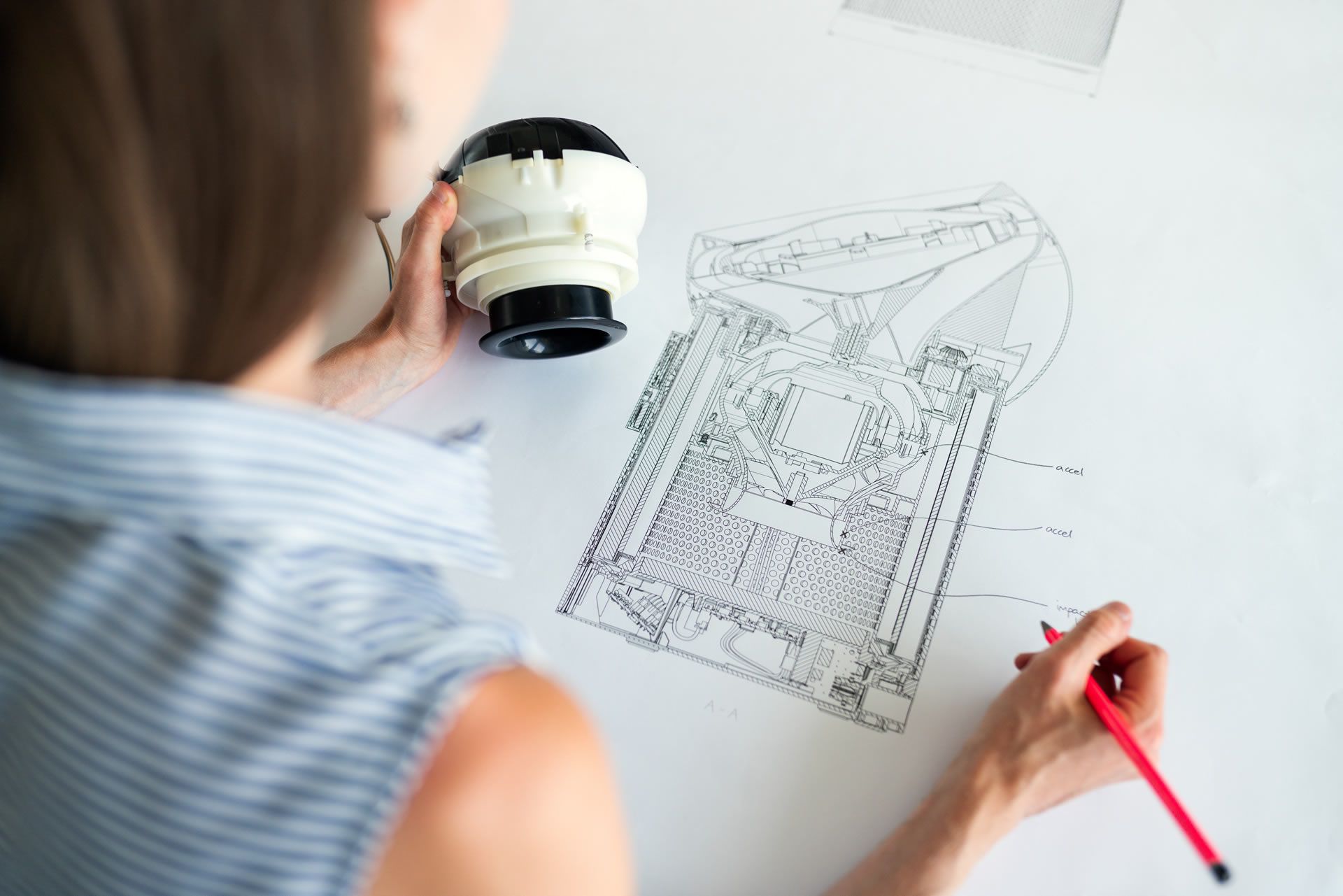

At Gerdes Kunststoff-Technik, process development and design work with powerful CAD, CAM and Moldflow simulation tools to get individual plastic injection moulded parts of the highest quality into series production faster and without costly prototypes and production errors.

In close cooperation with project management, development, design and manufacturing, we offer our customers innovative solutions and efficient production.

Gerdes Kunststoff-Technik maintains a close partnership with customers right from the early engineering phase for plastic injection moulding products.

Involvement in the planning phase avoids potential errors and obstacles, improves component integration and ultimately increases manufacturing efficiency.

To this end, we offer innovative solutions with the development partners within the Prettl Group and use CAD/CAM systems and Moldflow simulations for customer-oriented development and design of individual plastic injection moulded parts.

All advantages at a glance

-

Project Management & Engineering within the Group

-

All company processes certified to IATF 16949

-

In-house toolmaking for repair, maintenance, modification and servicing

-

Tool procurement worldwide, directly without intermediaries

-

Tool management logistics via sea, air and rail

Gerdes Kunststoff-Technik GmbH

+49 5262 940-0

Seit 2014 sind wir ein Mitglied der PRETTL-Unternehmensgruppe.