About Gerdes Technik

Gerdes has been present on the market since 1873. Today, the plastic injection moulding spectrum includes all standard and special thermoplastics in single and multi-component processes (1K/2K/3K).

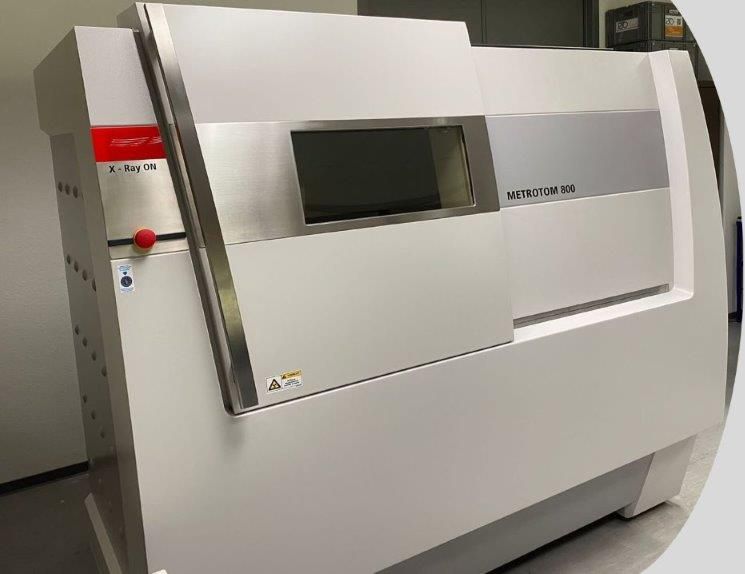

Our core competence lies in the production of technical functional parts and optical components in the field of vision. In both areas, the focus is on the quality requirements of our customers. Tight tolerances for technical components and the high-quality optics of visible parts are the guiding principles in our production and technology. In addition, we offer deep finishing with final assembly of subassemblies.

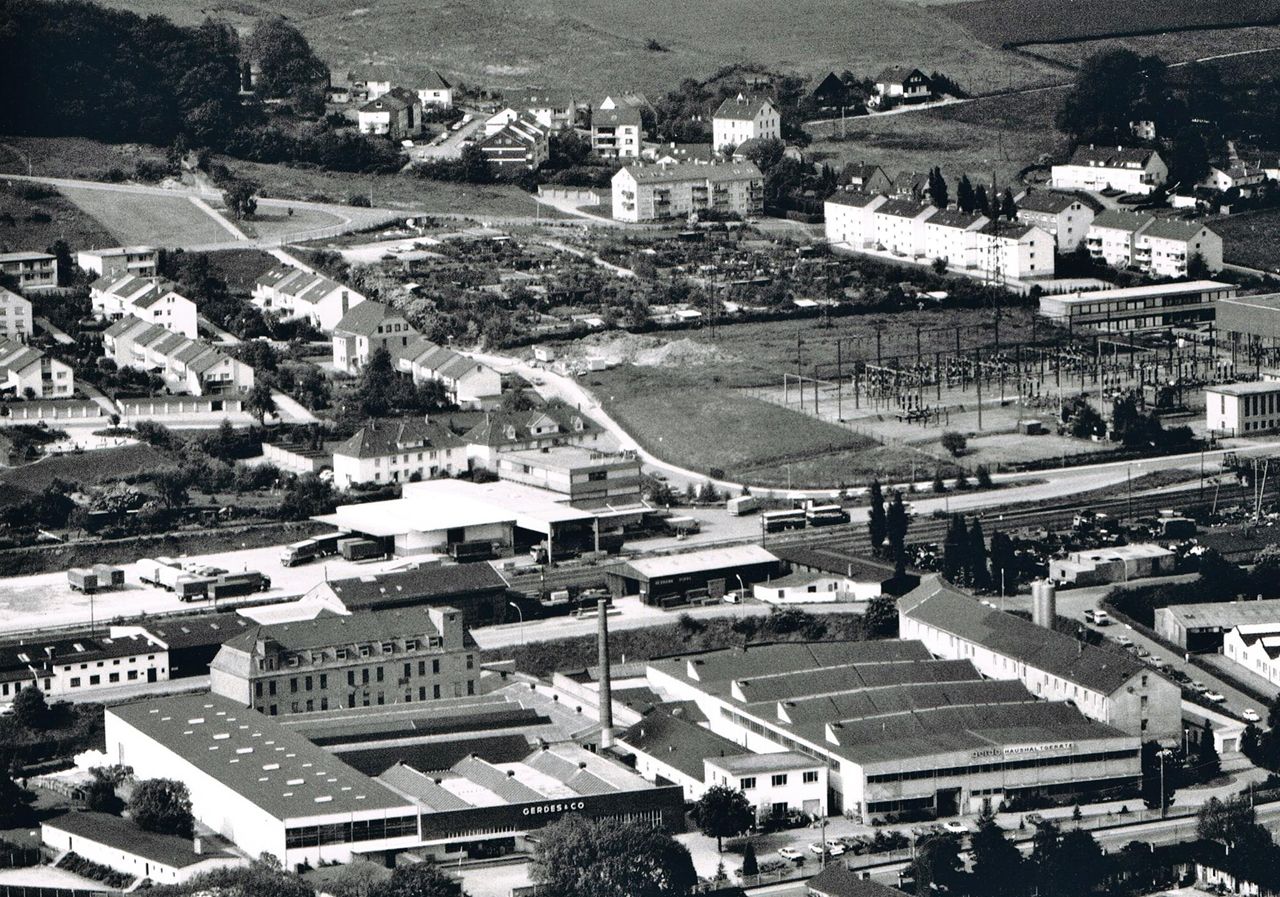

The key point for all activities of Gerdes Kunststoff-Technik is Extertal. Our company was founded here in 1959, initially as a further production site for our own household appliance brand GERDA from Schwelm, and then became independent in the further course of time.

With the aim of creating closer proximity to the growing Eastern European market for plastic injection moulding, a second production site was established in Poznan, Poland in 1997. This location produces plastic injection moulded components with the same high quality standards as in Extertal.

We process all customer enquiries centrally for you from Extertal.

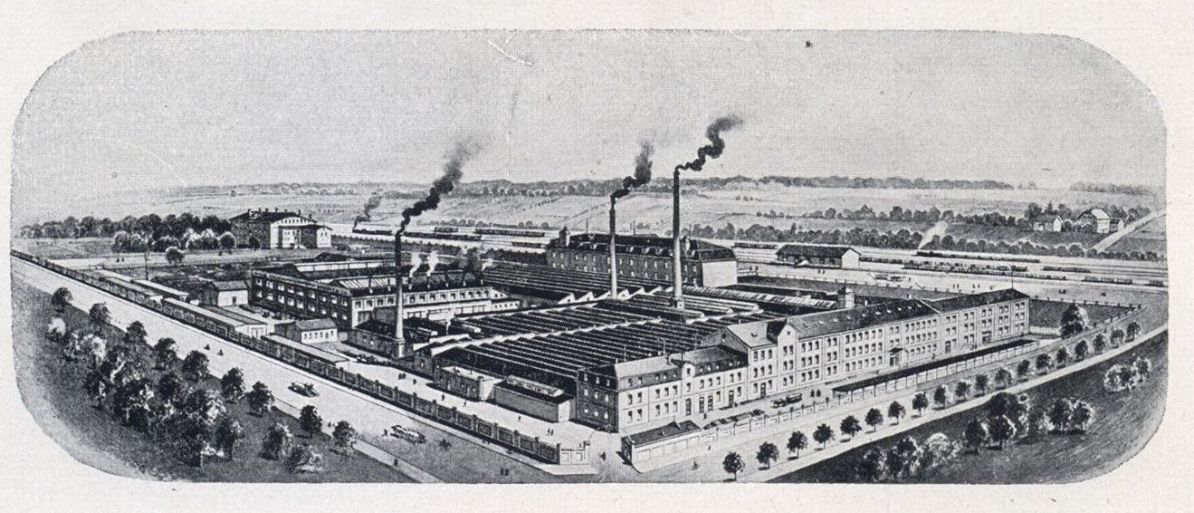

History

1959

Takeover from the Neizert family and Dr. Stürsberg, as part of the "East Westphalia Plan", as a pure manufacturing facility for thermosets for Gerda household appliances in Schwelm.

1995

Start of the production of 2K products

1997

Start of the production of 3K products

Founding of the branch factory in Poznan, initially as a JV and in 2000 takeover of 100% subsidiary of Gerdes.

2004

Expansion of the production area by 2,800 sqm in Extertal

2014

Eingliederung in die Prettl Gruppe

2020

GOZERO Strategy (Ziel: CO2 neutrale Produktion 2024)

2023

150th anniversary

Foundation of the branch factory in Łódź

Greetings on the occasion of the 150th anniversary

Gerdes Kunststoff-Technik GmbH

+49 5262 940-0

Seit 2014 sind wir ein Mitglied der PRETTL-Unternehmensgruppe.