Quality management

As a company that has been established on the market for many years, zero-defect tolerance is one of our basic principles. Therefore, we respect and appreciate a demanding quality management as the work step that completes the entire process sequence and guarantees the customer the desired quality. We use the systematics of continuous process monitoring with, among other things, a CT measuring machine.

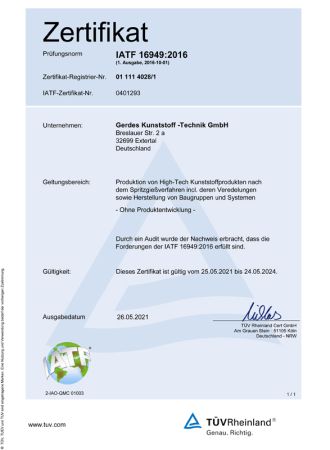

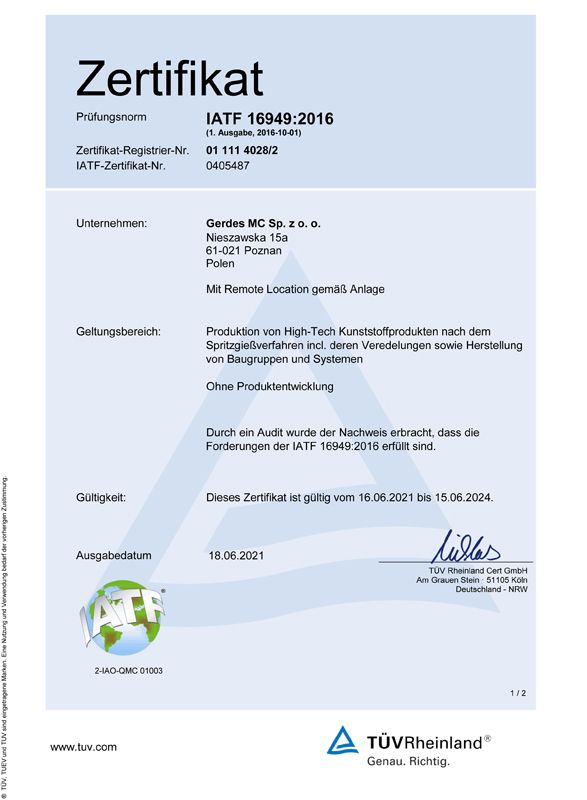

Our process flows are regularly checked by certifications according to IATF 16949, as well as by process and system audits of our customers. From the Failure Mode and Effects Analysis (FMEA) to the quality documentation in the outgoing goods department, the customer receives quality at the highest level.

Gerdes Kunststoff-Technik GmbH

+49 5262 940-0

Seit 2014 sind wir ein Mitglied der PRETTL-Unternehmensgruppe.